Oil Purifier (Fluid Disc Separation)

Fluid Disc Separator (Oil Purifier)

Fluid Disc Separator (Oil Purifier) FPRO series produced by VGO Smart is a revolutionary technology product, which uses the centrifugal principle to purify various solid, liquid, gaseous (such as: water in oil, impurities, etc.) and other pollutants in the contaminated oil, to achieve rapid separation, and is at the leading level in the domestic industry products. Fluid Disc Separator (Oil Purifier) is improved on the basis of the original separator, and the purification speed and degassing effect are improved to an unprecedented degree in the field.

The products in the offline state has been able to use oil purification to the United States NAS1638 class III aviation oil standard, and in multiple filtration, purification after the water content of up to 100PPM, the purified gas content is currently in the forefront of the country, and in the filter element, electricity and other aspects of the annual savings of hundreds of thousands to millions of costs.

The FPRO series of Fluid Disc Separator (Oil Purifier) mainly includes FPRO-30P, FPRO-40P, FPRO-40G.

Working Principle

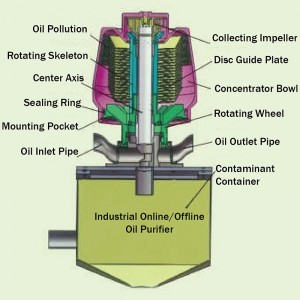

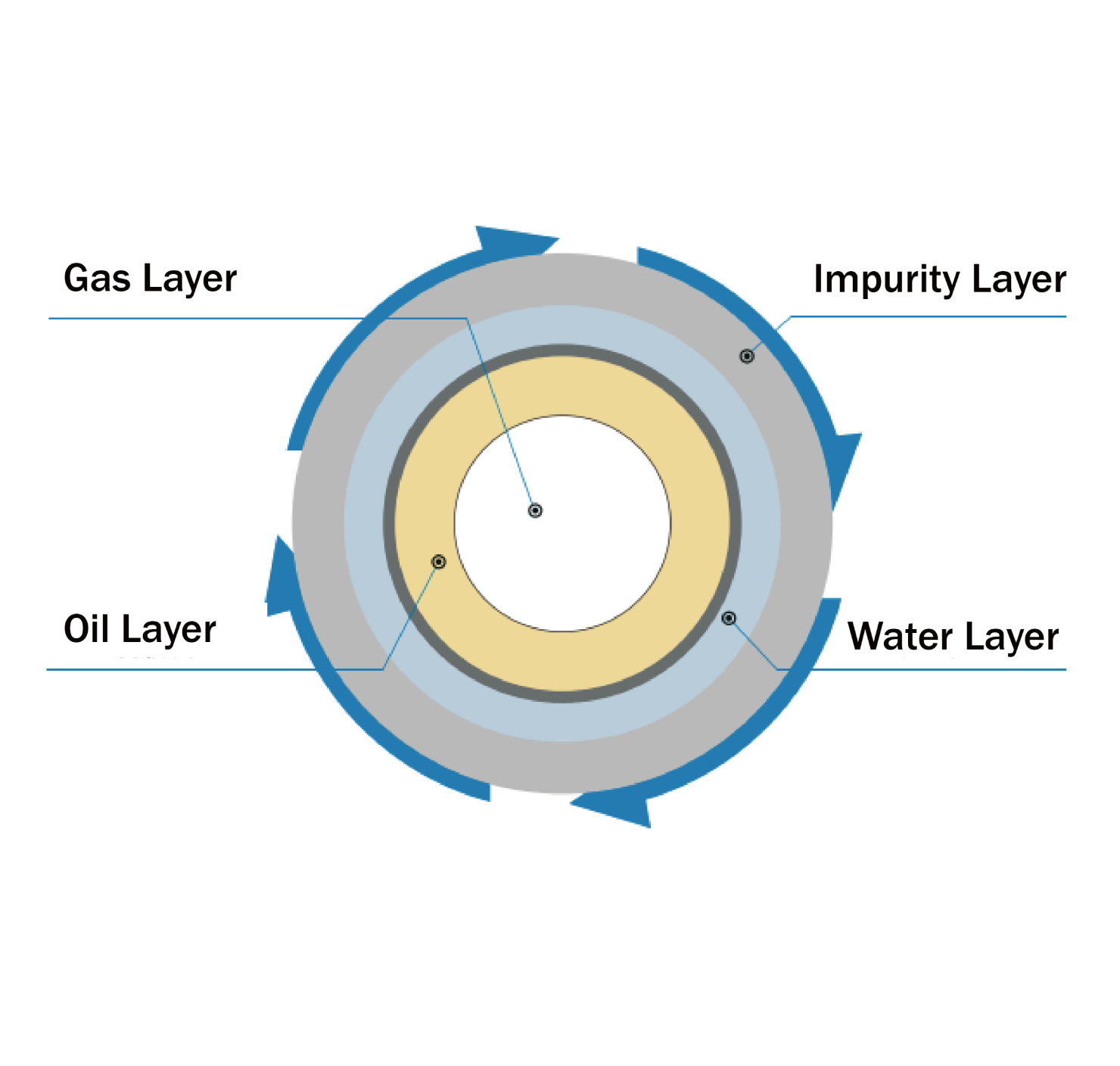

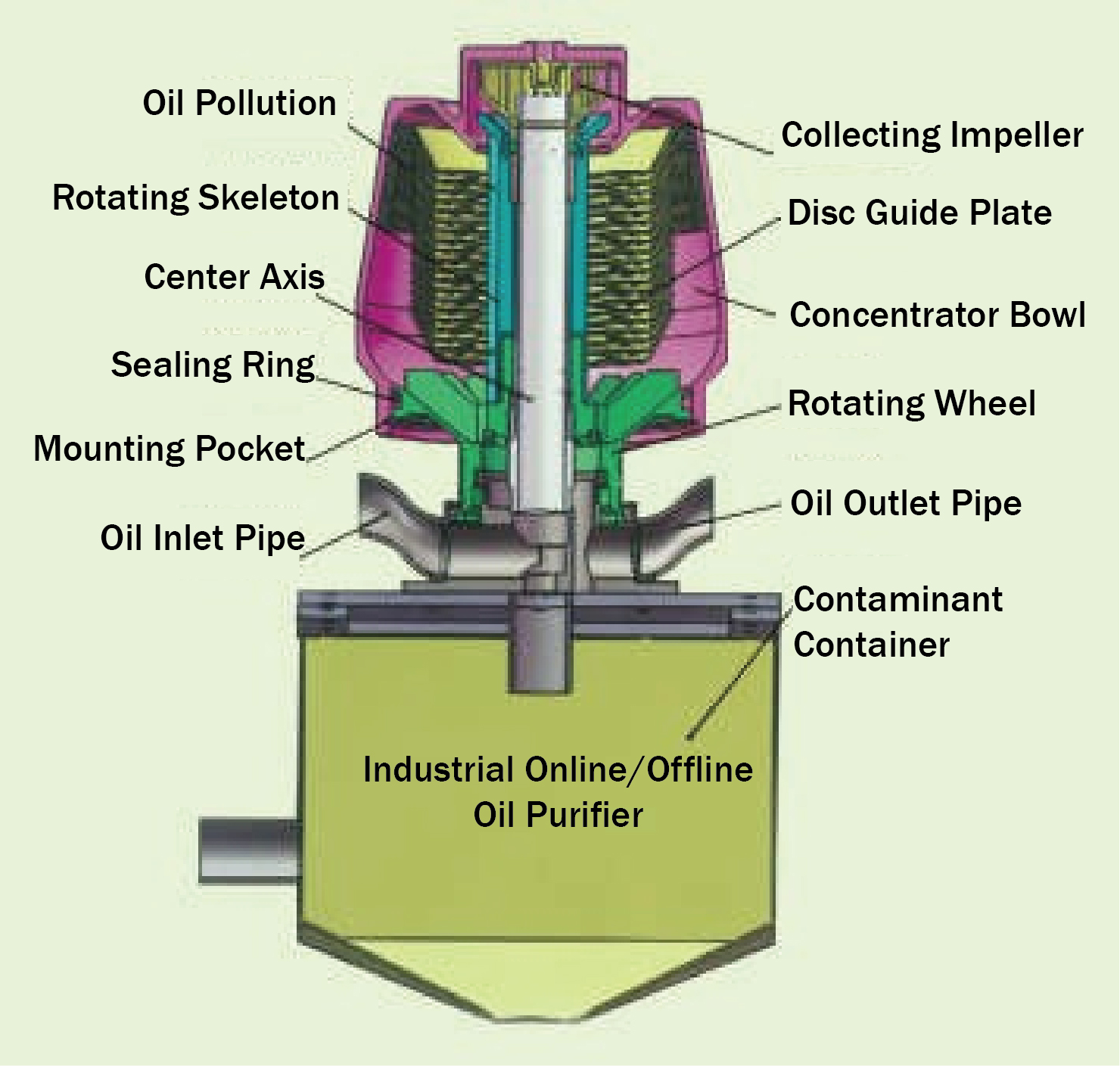

Fluid Disc Separator (Oil Purifier) is the use of centrifugal working principle. Using different material density of different characteristics, through the disc separation solid will particle with a density greater than the oil as well as water and air are separated from the oil. The specific working process is as follows: After the oil enters the oil pipe of the fluid disc separator from the customer's oil tank, under the action of negative pressure,it moves along the seal skeleton to the top of the centrifugal cylinder, and when it fills the entire cylinder cavity, the centrifugal cylinder begins to work. Under the action of centrifugal force, the oil rotates at a high speed to separate the dense particles and flow along the wall of the cylinder to the sewage container. At the same time, the oil that has just been preliminally purified is squeezed into the disc under the action of pressure, under the layer of filtration of the disc, the secondary purification is obtained, and the oil pipe is finally discharged, and the pressure is played back to the customer tank, and the water part will be thrown to the water removal hood by centrifugal force, so as to achieve online operation drainage. At this point, a filtering cycle is completed.

System Composition

Application

⚫FPRO-30P model equipment is suitable for steel metallurgy, electric power, Marine and shipping, non-ferrous metals, chemical industry, shipbuilding and other kinds of hydraulic oil purification, hydraulic parts cleaning, steam turbine, hydraulic turbine, hydraulic tank cleaning and other large industrial and manufacturing applications.

⚫FPRO-40P and FPRO-40G models are suitable for steel metallurgy, electric power, Marine and shipping, non-ferrous metals, chemical industry, shipbuilding and other kinds of hydraulic oil purification, hydraulic parts cleaning, hydraulic tank cleaning, turbine, turbine oil purification, wind power hydraulic system manufacturing and washing and other large industrial and manufacturing applications.

Technical Characteristics

Fluid Disc Separator (Oil Purifier) is a kind of high-quality purification equipment to ensure the normal operation of the hydraulic system. The working principle of its main application is to purify pollution particles, water and air quickly from the oil of the system. Fluid disc separator is a large viscosity, high water content of the oil purification has a strong pertinence, is used for hydraulic transmission system, servo system, various equipment lubrication system oil purification ideal equipment. The output flow rate of the fluid disc separator is not less than 36L/min, and the purification effect can reach NAS1638 3-8 level after purification if the purification mode is carried out, which fully meets the working requirements of the high-precision system.

Protection System

⚫Pressure relief protection: When unexpected oil pressure failure or oil leakage occurs during the operation of the equipment beyond the set pressure value, the protection system will automatically cut off the power supply and stop the operation of the equipment.

⚫Vibration protection: when abnormal vibration, jitter, resonance or decibel exceeds the value during the operation of the equipment, the protection system will automatically cut off the power supply and the equipment will stop running.

⚫Soft boot protection: When the device is started, this protection function will be enabled to avoid anomalies caused by instantaneous high speed.

Running Status Monitoring System

⚫The control panel is equipped with pressure digital display meter to monitor the operating pressure of the equipment at all times;

⚫The control panel is equipped with power supply, vibration protection, centrifugal cylinder motor, booster pump, oil return indicator, vacuum pump, phase sequence protection and other operating status indication information.

Technical Parameters

|

Functional Parameter |

FPRO-30P |

FPRO-40P |

FPRO-40G |

|

Rated Flow |

36-60L/min |

36-60L/min |

36-80L/min |

|

Working Power Supply |

Three-Phase Four-Wire System 380V |

||

|

Frequency /Rated Power |

50Hz/3KW |

50Hz/3KW |

50Hz/3KW |

|

Environment Temperature |

-20-80℃ |

-20-80℃ |

-20-80℃ |

|

Environment Humidity |

≤95% |

≤95% |

≤95% |

|

Cylinder Speed |

≥8000r/min |

≥8000r/min |

≥8000r/min |

|

Protective System |

Phase Sequence, Vibration protection, Soft Star |

Phase Sequence, Pressure Relief, Vibration Protection, Soft Start |

|

|

Oil Viscosity Range |

25-320#CSt |

25-460#CSt |

25-680#CSt |

|

Slag Removal NAS Grade |

3-8 |

3-8 |

3-8 |

|

Drainage Efficiency |

|

96.10% |

99.98% |

|

Drainage Method |

|

Automatic Continuous Drainage |

High-speed Automatic Continuous Drainage |

|

Import oil Pressure |

Vacuum Degree≤0.05Mpa |

Vacuum Degree≤0.05Mpa |

Vacuum Degree≤0.05Mpa |

|

Max Output Pressure |

≤0.40Mpa |

≤0.40Mpa |

≤0.40Mpa |

|

Min Output Pressure |

≥0.15Mpa |

≥0.15Mpa |

≥0.15Mpa |

|

Imbibition Height |

≤8m |

≤8m |

≤8m |

|

Applicable Oil |

Hydraulic Oil/Turbine Oil/Lubricating Oil/Gear Oil |

Hydraulic oil/Turbine Oil/Lubricating Oil/Gear Oil/Oil Film Bearing Oil |

|

|

Specification of Equipment |

1015x622x943mm |

1015x622x943mm |

1015x622x943mm |

|

Installation (unit) Weight |

≤320KG |

≤320KG |

|

Selection Comparison Table

| Functional Parameter |

FPRO-30P |

FPRO-40P |

FPRO-40G |

|

Slag Removal Function |

YES |

YES |

YES |

|

Degasification |

YES |

YES |

YES |

|

Water Removal Function |

NO |

YES |

YES |

|

Pollution Degree of Solid Particles |

0 |

NAS 3-8 |

NAS 3-8 |

|

Slag Gas Separation Efficiency |

99.0 % |

99.7 % |

99.97 % |

|

Water Separation Efficiency |

Low |

Middle |

High |

|

Quantity of Flow |

30-45L/min |

45-60L/min |

45-60L/min |

|

Viscosity Range |

3-460mm²/s |

3-680mm²/s |

3-680mm²/s |

|

Phase Sequence Protection |

YES |

YES |

YES |

|

Vibration Protection |

NO |

YES |

YES |

|

Pressure Relief Protection |

NO |

YES |

YES |

|

Motor Type |

Chinese Domestic Motor |

Germany ABB Motor |

Germany ABB Motor |

|

Rotate Speed |

8000r/min |

8000r/min |

10000r/min |

|

Versions |

3.0 |

4.0 |

4.0 |

Overview of Technical Advantages

⚫Support online/offline purification mode, no consumables, no vacuum heating, subvert traditional industries, revolutionary high-tech products.

⚫Easy to move, easy to operate, can be used online or offline.

⚫Impurity removal method adopts disc separator cylinder 8000-10000 RPM separation to exclude NAS grades up to 3-8.

⚫Liquid removal method The disc separator can automatically and continuously drain at a high speed, and exclude a large amount of free water. The remaining trace water in the centrifugal zone is rapidly vaporized by the action of liquid friction heat, and is excluded by the booster pump.

⚫Compared with the vacuum type oil purifier and the traditional centrifugal oil purifier, the fluid disc separator series has a larger sewage capacity, and the sewage box capacity can reach 3.0kg.

⚫Low maintenance cost, clean pollutants 3.0kg, cleaning the centrifugal cylinder cost less than 10 yuan, each cleaning about 5-10 minutes. The product can save costs for users and improve economic benefits. The oil purification does not require heating and does not change the oil's grease. Under the condition of unchanged physical and chemical properties, the trial life of the oil can be improved.

⚫After the solid impurities are cleaned up, the equipment is kept in good operation. The life of pump and motor is increased by 4-10 times, the life of hydraulic transmission components is increased by 10 times, the life of valve is increased by 5-300 times, the fatigue life of roller bearing is extended by 50 times, the fatigue life of radial bearing is extended by 10 times, and the life of oil is extended by > 2-3 times.

⚫The product has extremely high safety, equipped with multi-functional protection, such as phase sequence protection, pressure relief protection, vibration protection and other protection systems, no heating device, no fire hazards, no concentrated pollution caused by filter rupture.

⚫Remove pollutants, environmental protection and clean pollution-free.

Comparison of Net Oil Effect Used On Site

46#Steam Turbine Oil

46#Hydraulic Oil

46#Hydraulic Oil

46#Steam Turbine Oil

220#Lubricating Oil